30

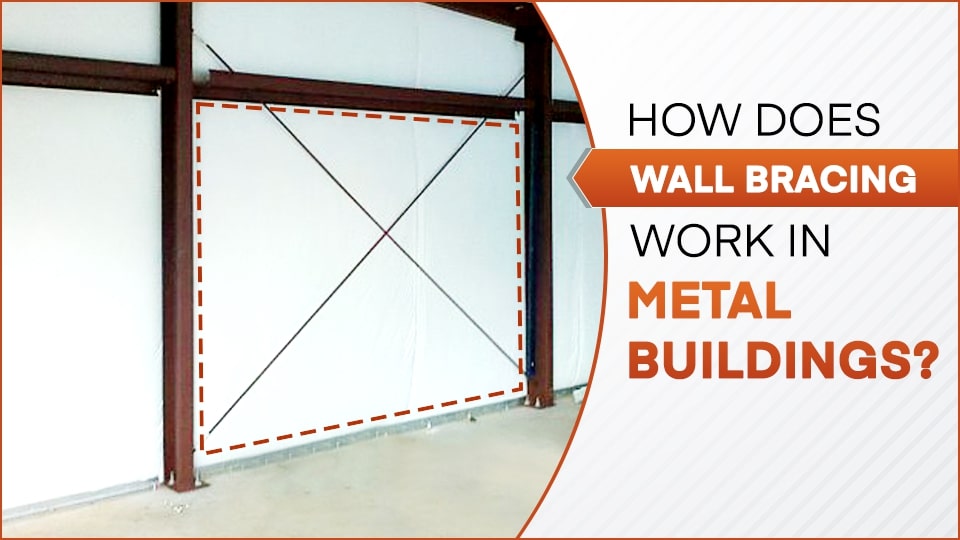

How Does Wall Bracing Work in Metal Buildings?

When it comes to a practical building solution, you’d be hard-pressed to find a better solution than going with metal as a building material. It’s amazingly durable, reliable, and cost-effective and is a perfect choice for nearly any building purpose you may have in mind. You probably know that many carports and garages are now constructed with steel. Still, steel buildings are also being engineered and installed across the U.S. for all sorts of uses and applications!

How does wall bracing work?

Steel building components are naturally stronger and more resilient than those made of wood. But any building design still requires some bracing and reinforcements for structural stability. The bracing point is to transfer the stress of loads placed upon the walls from brace to brace, thus dispersing the force of the load at any single point. Every building, regardless of size, needs to resist stress loads to keep standing tall.

The forces that are common to building walls break down into two categories: longitudinal (up and down) and lateral (side to side). The most common longitudinal forces include gravity (downwards force) and wind uplift (upwards force). Horizontal wind and seismic activity are common lateral forces that can act upon the walls and foundation, causing it to rock from side to side.

The bracing used to help support these building walls against both longitudinal and lateral forces can take several forms, but two of the most common are steel rods or cables. These are inserted diagonally into the frame to make an “X” shape from the eave strut to the wall columns. The rods and/or cables will receive the load at one end and then pass it along to the next brace or frame member, thus distributing and dispersing the load across the wall. How many braces applied will depend upon a few factors, including the building’s size and its intended uses and applications.

Bracing is explained in terms of real-world conditions.

If wind pushes against one wall, it also creates a simultaneous pull force on the opposite wall. In a four-walled building, the other two remaining walls are the bracing walls, and their job is to help keep the structure from moving. Underground seismic activity can create a similar effect. Earthquake waves can cause the foundation to shift underneath the walls above, creating essentially the same lateral forces as winds blowing against an exterior wall.

Since wind and seismic activity can potentially arrive from any direction, every wall must have the capability to act as a brace when needed. The forces every structure must be able to withstand include torsion, compression, shear, and lift. Many smaller steel buildings can maintain structural integrity with nothing more than the combined action of the four walls and the roof. Larger buildings – including all 60 feet wide or greater – require additional strengthening in the form of added bracing.

Bracing Systems & Types

There are two main bracing systems used to stabilize structures against external forces: vertical and horizontal. These systems accomplish their goals through several bracing types, depending upon what the building’s individual needs call for. These bracing types include single diagonals, cross-bracing, V-bracing, K-bracing, and eccentric bracing. Each major bracing system and bracing type is further explained below:

BRACING SYSTEMS

- Vertical

With a vertical bracing system, the bracing is placed vertically between columns to transfer horizontal forces down to the foundation and into the ground. In the case of a light-gauge steel building, this is often accomplished by using square metal tubing.

- Horizontal

Horizontal bracing is typically placed at the ground level and every subsequent floor level. The roof level may sometimes need horizontal bracing as well. The horizontal bracing system serves to transfer horizontal forces to the vertical bracing planes. With light-gauge steel buildings, horizontal bracing usually involves square metal tubing, metal hat channels, or both.

BRACING TYPES

- Single Diagonals

Also known as triangulation, single diagonals are often comprised of a series of trusses. Essentially, diagonal members are inserted into rectangular frame areas to create greater stabilization. These diagonals are designed to be able to resist both tension and compression. In many steel building cases, diagonal members take the form of either U-shaped or C-shaped metal channels. These channels are also utilized in both V-bracing and K-bracing, as well.

- Cross-Bracing

Also known as X-bracing, cross-bracing involves inserting two diagonal members who cross at a midpoint. Each cross-brace member only has to resist tension, so steel cables are often used as the preferred method of cross-bracing. One downside of this method is that it can reduce the amount of available, usable space within a particular wall façade or opening.

- V-Bracing

With V-bracing, two diagonal members extend from the top corners of a horizontal member and then meet at a midpoint on a lower horizontal beam. Inverted V-bracing (or chevron bracing) is another similar method that’s commonly used, as well.

- K-Bracing

K-braces connect to vertical columns towards the middle and create a sideways “V” pattern that also looks like a “K” when viewed in conjunction with the columns. K-braces are great for adding stability in general, but they aren’t the best solution for regions that experience more seismic activity.

- Eccentric Bracing

Eccentric bracing is a better solution for enduring seismic forces, and it’s designed in a pattern similar to V-bracing. The difference is that braces connect to separate places on the beam, so it’s better at enduring and dispersing energy from rolling seismic waves. Single diagonals are also sometimes utilized within an eccentric bracing approach.

Turn to Carport Central for all your steel building & steel structure needs!

Ready to move forward with getting your own custom metal building, but not sure which building partner can best take care of your needs? Look no further than the team of professionals at Carport Central! Our trained building specialists can help you to decide which building plan and size will work best for your individual situation, and our in-house engineers will help ensure that your building has all the needed bracing and supports to meet any wind load, snow load, or other force considerations which may be required in your locality. We’ve got a ton of popular product styles and offerings, and we also have the capability to allow you to design your own custom steel structure from the ground up with the help of our cutting-edge, easy-to-use 3D Building Design Tool!

How much usable interior space do you need with your steel structure? Size is really no object with Carport Central; we can provide buildings that are 70’ wide, 100’ wide, even up to 300’ wide if that’s what you need! The length and height of your structure are completely customizable as well. And speaking of custom metal building applications, our customers across the United States are using their buildings like carports, garages, barns, workshops, warehouses, manufacturing facilities, office buildings, retail storefronts, residences, barndominiums, commercial buildings, and much more! The only real limit to the possibilities is your imagination!

You can reach out to us online, or give us a call at (980) 321-9898 and speak with one of our friendly building specialists today! We invite you to experience the Carport Central difference for yourself!

Get Started

It's fast and easy. Get your instant quote today!

BLOG TOPICS

- Metal Building Extensions (1)

- Install of the month (2)

- Garages (52)

- Farm Show (1)

- Building Components (1)

- Carports (29)

- Storage Sheds (15)

- Metal Buildings (6)

- Barns (18)

- Metal Homes (8)

- Metal Sheds (1)

- RV Covers (6)

- 12 Gauge Framing (7)

- Workshops (7)

- Eagles & Buildings (1)

- Reviews (2)

- Snowfall in the Southeast (2)

- Carports and Buildings Prices (1)

- Reality Of Discounted Buildings (2)

- Snow Removal (1)

- Offers (3)

- Condensation in Metal Buildings (2)

- News & Awards (12)

- Livestock sheds (4)

- Installations (15)

- Metal Buildings Applications (7)

- Customized Buildings (41)

- Carport Sizes (2)

- Facts (1)

- Certified Carports (2)

- COVID-19 (1)

- Prefab Metal Buildings (66)

- Metal Building Homes (6)

- Metal Building of the Week (11)

- Install of the week (1)

Metal Buildings

- Alabama

- Arizona

- Arkansas

- California

- Colorado

- Connecticut

- Delaware

- Florida

- Georgia

- Idaho

- Illinois

- Indiana

- Iowa

- Kansas

- Louisiana

- Maine

- Maryland

- Massachusetts

- Michigan

- Minnesota

- Mississippi

- Missouri

- Montana

- Nebraska

- Nevada

- New Hampshire

- New Jersey

- New Mexico

- New York

- North Carolina

- North Dakota

- Ohio

- Oklahoma

- Oregon

- Pennsylvania

- Rhode Island

- South Carolina

- South Dakota

- Tennessee

- Texas

- Utah

- Vermont

- Virginia

- Washington

- West Virginia

- Wisconsin

- Wyoming

Metal Garages

- Alabama

- Arizona

- Arkansas

- California

- Colorado

- Connecticut

- Delaware

- Florida

- Georgia

- Idaho

- Illinois

- Indiana

- Iowa

- Kansas

- Louisiana

- Maine

- Maryland

- Massachusetts

- Michigan

- Minnesota

- Mississippi

- Missouri

- Montana

- Nebraska

- Nevada

- New Hampshire

- New Jersey

- New Mexico

- New York

- North Carolina

- North Dakota

- Ohio

- Oklahoma

- Oregon

- Pennsylvania

- Rhode Island

- South Carolina

- South Dakota

- Tennessee

- Texas

- Utah

- Vermont

- Virginia

- Washington

- West Virginia

- Wisconsin

- Wyoming

Metal Carports

- Alabama

- Arizona

- Arkansas

- California

- Colorado

- Connecticut

- Delaware

- Florida

- Georgia

- Idaho

- Illinois

- Indiana

- Iowa

- Kansas

- Louisiana

- Maine

- Maryland

- Massachusetts

- Michigan

- Minnesota

- Mississippi

- Missouri

- Montana

- Nebraska

- Nevada

- New Hampshire

- New Jersey

- New Mexico

- New York

- North Carolina

- North Dakota

- Ohio

- Oklahoma

- Oregon

- Pennsylvania

- Rhode Island

- South Carolina

- South Dakota

- Tennessee

- Texas

- Utah

- Vermont

- Virginia

- Washington

- West Virginia

- Wisconsin

- Wyoming

- 100x100 Metal Building

- 12x12 Metal Shed

- 12x20 Carport

- 12x24 Carport

- 12x30 Carport

- 16x20 Carport

- 18x20 Carport

- 20x20 Carport

- 20x20 Metal Building

- 20x30 Carport

- 20x30 Metal Building

- 20x40 Carport

- 20x40 Metal Building

- 24x24 Carport

- 24x24 Garage

- 24x30 Carport

- 24x30 Metal Building

- 24x30 Metal Garage

- 24x36 Metal Building

- 26x30 Metal Building

- 30x30 Carport

- 30x30 Garage

- 30x30 Metal Building

- 30x40 Carport

- 30x40 Garage

- 30x40 Metal Building

- 30x40 Storage Building

- 30x50 Metal Building

- 30x60 Metal Building

- 40x100 Metal Building

- 40x40 Metal Building

- 40x60 Metal Building

- 40x80 Metal Building

- 50x100 Metal Building

- 50x50 Metal Building

- 50x80 Metal Building

- 60x100 Metal Building

- 60x120 Steel Building

- 60x60 Metal Building

- 60x80 Metal Building

- 80x100 Metal Building

- All Steel Carports

- American Building Network

- American Custom Carports

- American Steel Carports

- Arkansas Carports

- Best Choice Metal Structures

- California All Steel

- Carports Outlet

- Central Texas Metal Buildings

- Coast To Coast Carports

- Custom Steel Structures

- Dreams Carports and Buildings Inc

- East Coast Carports

- Enterprise Steel Structures

- Infinity Carports

- Interstate Steel Structures

- Long Horn Buildings

- Midwest Steel Carports

- NC Structures

- New Team Carports

- Northside Metal Carports

- Quality Carports

- Rhino Carports

- Safeguard Metal Buildings

- Southern Steel Buildings Inc.

- Steel Buildings and Structures

- Tennessee Steel Buildings

- Tubular Building Systems

- Ultimate Metal Buildings

- United Structures

- USA Carports