09

The Lowdown on Wind Uplift Ratings for Metal Buildings

Everyone wants to feel safe. It really doesn’t matter what kind of building you’re in, whether it’s a home, garage, or other types of structure – safety and security are still of utmost importance. One of the things that make us feel the safest is knowing that we have a reliable roof over our heads. But what if we didn’t? That’s the real possibility you’d be facing if your metal building weren’t certified to meet certain wind uplift ratings.

Wind uplift ratings are a set of systems that explain how much wind force and suction a roof can withstand. The higher the rating, the more pressure the certified metal building’s roof can take. These ratings aren’t meant to be a 100% guarantee, but they are the best way to gain more peace of mind in knowing that your roof will stay put in the face of wind and weather threats.

What is Wind Uplift?

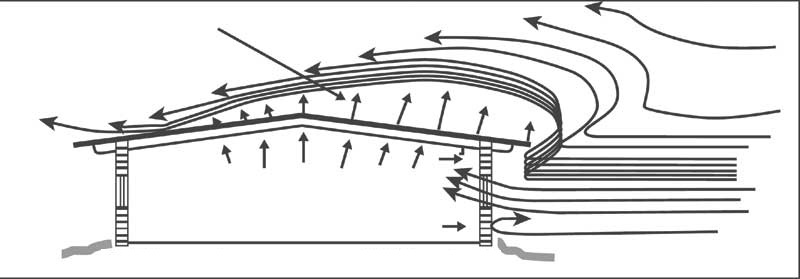

Wind uplift is a common issue faced by buildings and structures of all types, but it’s also something that not everyone knows how to define. Essentially, wind uplift is the pressure exerted on a structure when the wind hits it horizontally, going both under and over the roof simultaneously. This wind motion creates a pressure differential around your roof; the net force applied beneath the roof becomes greater than the force pressing down upon it. In extreme cases, this phenomenon can result in lifting the roof right off of a building!

You’re probably wondering what factors affect this phenomenon? Well, we’re glad you asked! There are four main factors where the building itself is concerned, which we’ve broken down for you below:

1. The Building’s Height

The taller your prefab metal building, the more wind it will probably face. This is mainly due to the fact that wind speeds tend to increase as elevation above the Earth’s surface increases.

2. The Building’s Location

Your site location also has a lot to do with how much wind uplift your metal building or metal building kit experiences. Locations that are elevated, frequently experience severe weather, or are just generally windy will experience more potential wind uplift impact. On the other hand, low-lying areas with generally still air are much less likely to experience damaging wind uplift.

3. The Building’s Surroundings

Another factor that affects the amount of wind uplift your metal building may experience is what the surrounding terrain looks like. A building in an area that’s surrounded by taller buildings and structures is much less susceptible to wind uplift than a building placed out in an open field. This should come as no great surprise; areas of dense construction help to break up wind flow, whereas wide-open spaces have no buffer to offer where wind convection is concerned.

4. The Building’s Openings

One factor that many don’t consider when it comes to wind pressure is building openings. In terms of metal structures, the more open faces and cutouts you have in your building, the more wind pressure can potentially build inside of your structure. The best way to prevent intense internal wind pressure issues to have your structure fully enclosed.

What Affects Wind Uplift?

Wind uplift ratings aren’t determined arbitrarily. Instead, engineers have a list of specific factors they consider when it comes to planning for wind uplift pressure issues.

Societal Risk

The first thing an engineer will consider is how much of a risk that building’s roof would be to the humans inside if the roof were to fail. These risks help engineers sort buildings into four basic categories:

- Category I buildings pose little threat to humans if they fall, and are typically the structures that have the least amount of impact in the event of a natural disaster. Storage sheds typically fall in this category, for example.

- Category II buildings typically encompass most residential homes, office buildings, and business facilities. This category is the “catch all” category, as it contains any building that isn’t specifically categorized as Level I, III, or IV.

- Category III buildings pose a greater risk to human life in the event of a collapse. These are the buildings necessary for a functioning society, including things like schools, water plants, and waste treatment plants.

- Category IV buildings are those which are built to the highest structural standards. These include large structures which are essential to supporting the community in the event of a natural disaster, and include things like hospitals, other medical treatment facilities, police stations, fire stations, and designated hurricane shelters.

Positioning

Since a building’s surroundings affect how much wind uplift it experiences, engineers also consider a building’s positioning when determining wind uplift pressure needs.

There are three common positioning categories: B, C, and D.

- B – Buildings in this category are close together, typically in an urban or suburban setting.

- C – Buildings in this category are near some obstructing factor, but aren’t constructed as densely as typical urban or suburban settings. Buildings in this category are also less than 30 feet tall.

- D – Buildings in this category are located in unobstructed, flat areas which pose little to no hurricane risk.

Other Considerations

There are some other factors that engineers use, as well. These factors don’t fit neatly into any one category, but all are also important when it comes to determining a metal building’s wind uplift rating:

- Lots of openings can worsen wind uplift pressure

- Steep slopes worsen wind uplift pressure

- Unusual roof surfaces can either negatively or positively affect your building’s wind uplift rating

- Parapet walls lessen the effects of wind uplift pressure

What Determines Wind Uplift Ratings?

We’ve already discussed the things that engineers consider when determining wind uplift ratings, but it’s important to talk about what kinds of tests are actually conducted to help make final determinations. There are five commonly-used tests, each of which is explained below:

1. UL-580

The UL-580 is one of the most well-known tests for wind uplift pressure. This standard test has been around since 1973, and uses a 10’x10’ piece of the metal building’s roofing to determine the wind uplift rating. It’s a straightforward process where the 10’x10’ square is subjected to constant uplift pressure for 5 minutes, then subjected to oscillating pressure for one hour. The oscillating pressures occur for ten seconds at a time. It’s ultimately the roofing’s response to these oscillating pressures which determine what class the roof is. The three common classes are 30, 60, and 90.

- Class 30 withstands a constant pressure of 30 psf, and oscillating pressures between 22 and 42 psf

- Class 60 withstands a constant pressure of 60 psf, and oscillating pressures between 44 and 83 psf

- Class 90 withstands a constant pressure of 90 psf, and oscillating pressures between 66 and 90 psf

2. ASTM E 1592

This test is used to determine the strength of the anchors and panels. In order to do so, a 10’x25’ panel set with intermediate supports is subjected to pressure from underneath. This process goes on, and the pressure is increased until the panels eventually fail. This helps engineers determine what maximum wind pressure the panels and anchors can withstand.

3. FM Global Standard 4471

This test is conducted to meet the approval standards set by the insurance company Factory Mutual Global. It’s a more intensive test than the previous two. It starts by setting up a 5’x9’ section of framing, with a 22-gauge steel roof attached to its purlins. The sample is then insulated and fitted to a pressure device. The device subjects the sample to 15 psf for one minute. The pressure is then increased in increments of 15 psf, until the sample can no longer withstand it. Ultimately, the metal building’s wind uplift rating will be whatever level was reached before the final psf increase caused the sample to break.

It’s important to note that this test requires the edges and corners of a metal building’s roof to be reinforced and thus able to withstand greater wind uplift than the rest of the roof.

ASCE 7-16

The ASCE 7-16 is another test used to ascertain the effects of wind uplift pressure on roof assemblies. While most often used on single panel roofs, this test can also be conducted on most any type of shingle roof as well.

UL 1897

The UL 1897 test is used to determine whether or not the metal building’s roof meets the wind uplift rating standards of the International Residential Code. The wind uplift resistance mark is defined as the level reached before the fasteners are pulled loose.

There’s More to Consider Than Uplift

Certified metal buildings and metal building kits are affected by more than just wind uplift. They are also affected by side wind loads. Wind load is the force exerted directly onto a structure by wind. This comes in two main forms: shear load and lateral load.

Shear load is the wind force that can cause racking or tilting.

Lateral load is the wind force that can shift a building off its foundation, or even overturn it through continual pushing and pulling.

If you live in an area that’s more prone to experience high winds, you certainly want to make sure that your building has a high wind uplift rating, a high shear load rating, and a high lateral load rating. If not, you could really be taking an unnecessary risk with your building.

Here at Carport Central, we want you to know that all of our custom metal buildings are engineered to meet or exceed any minimum wind load requirements which may apply in your local area. All of our premium steel buildings are fabricated to be durable, and are built to stand strong against all of Mother Nature’s typical threats.

Don’t Forget the Accessories

You also need to consider any accessories included on your roof when considering wind uplift ratings. Features such as ventilators, louvers, and cupolas will also need to be engineered to withstand strong wind uplift if you live in a particularly windy area, or an area that’s more prone to severe weather.

These roof accessories can be verified for wind resistance with the ASTM E330-02 test. It measures the constant wind uplift pressure that roof accessories like these can withstand.

Stand Strong with Carport Central

Looking for a building that will stand strong in the face of strong winds, heavy precipitation, and whatever else may come your way? Then what you really want is a metal building or metal building kit from Carport Central! Carport Central is known as the premier metal building provider in the nation for a reason. Unlike some other providers you’ll find, we only provide first-class steel structures, and we deliver stellar customer service, too. Our metal building specialists are true experts in their field, and they’re always standing by to answer any questions you may have. So, what are you waiting for? There’s no better time to find your perfect metal building solution than right now! Go ahead and give us a call today at (980) 321-9898!

Get Started

It's fast and easy. Get your instant quote today!

BLOG TOPICS

- Workshops (7)

- Eagles & Buildings (1)

- Reviews (2)

- Snowfall in the Southeast (2)

- Carports and Buildings Prices (1)

- Reality Of Discounted Buildings (2)

- Snow Removal (1)

- Offers (3)

- Condensation in Metal Buildings (2)

- News & Awards (12)

- Livestock sheds (4)

- Installations (15)

- Metal Buildings Applications (7)

- Customized Buildings (41)

- Carport Sizes (2)

- Facts (1)

- Certified Carports (2)

- COVID-19 (1)

- Prefab Metal Buildings (66)

- Metal Building Homes (6)

- Metal Building of the Week (11)

- Install of the week (1)

- Metal Building Extensions (1)

- Install of the month (2)

- Garages (52)

- Farm Show (1)

- Building Components (1)

- Carports (29)

- Storage Sheds (15)

- Metal Buildings (6)

- Barns (18)

- Metal Homes (8)

- Metal Sheds (1)

- RV Covers (6)

- 12 Gauge Framing (7)

Metal Buildings

- Alabama

- Arizona

- Arkansas

- California

- Colorado

- Connecticut

- Delaware

- Florida

- Georgia

- Idaho

- Illinois

- Indiana

- Iowa

- Kansas

- Louisiana

- Maine

- Maryland

- Massachusetts

- Michigan

- Minnesota

- Mississippi

- Missouri

- Montana

- Nebraska

- Nevada

- New Hampshire

- New Jersey

- New Mexico

- New York

- North Carolina

- North Dakota

- Ohio

- Oklahoma

- Oregon

- Pennsylvania

- Rhode Island

- South Carolina

- South Dakota

- Tennessee

- Texas

- Utah

- Vermont

- Virginia

- Washington

- West Virginia

- Wisconsin

- Wyoming

Metal Garages

- Alabama

- Arizona

- Arkansas

- California

- Colorado

- Connecticut

- Delaware

- Florida

- Georgia

- Idaho

- Illinois

- Indiana

- Iowa

- Kansas

- Louisiana

- Maine

- Maryland

- Massachusetts

- Michigan

- Minnesota

- Mississippi

- Missouri

- Montana

- Nebraska

- Nevada

- New Hampshire

- New Jersey

- New Mexico

- New York

- North Carolina

- North Dakota

- Ohio

- Oklahoma

- Oregon

- Pennsylvania

- Rhode Island

- South Carolina

- South Dakota

- Tennessee

- Texas

- Utah

- Vermont

- Virginia

- Washington

- West Virginia

- Wisconsin

- Wyoming

Metal Carports

- Alabama

- Arizona

- Arkansas

- California

- Colorado

- Connecticut

- Delaware

- Florida

- Georgia

- Idaho

- Illinois

- Indiana

- Iowa

- Kansas

- Louisiana

- Maine

- Maryland

- Massachusetts

- Michigan

- Minnesota

- Mississippi

- Missouri

- Montana

- Nebraska

- Nevada

- New Hampshire

- New Jersey

- New Mexico

- New York

- North Carolina

- North Dakota

- Ohio

- Oklahoma

- Oregon

- Pennsylvania

- Rhode Island

- South Carolina

- South Dakota

- Tennessee

- Texas

- Utah

- Vermont

- Virginia

- Washington

- West Virginia

- Wisconsin

- Wyoming

- 100x100 Metal Building

- 12x12 Metal Shed

- 12x20 Carport

- 12x24 Carport

- 12x30 Carport

- 16x20 Carport

- 18x20 Carport

- 20x20 Carport

- 20x20 Metal Building

- 20x30 Carport

- 20x30 Metal Building

- 20x40 Carport

- 20x40 Metal Building

- 24x24 Carport

- 24x24 Garage

- 24x30 Carport

- 24x30 Metal Building

- 24x30 Metal Garage

- 24x36 Metal Building

- 26x30 Metal Building

- 30x30 Carport

- 30x30 Garage

- 30x30 Metal Building

- 30x40 Carport

- 30x40 Garage

- 30x40 Metal Building

- 30x40 Storage Building

- 30x50 Metal Building

- 30x60 Metal Building

- 40x100 Metal Building

- 40x40 Metal Building

- 40x60 Metal Building

- 40x80 Metal Building

- 50x100 Metal Building

- 50x50 Metal Building

- 50x80 Metal Building

- 60x100 Metal Building

- 60x120 Steel Building

- 60x60 Metal Building

- 60x80 Metal Building

- 80x100 Metal Building

- All Steel Carports

- American Building Network

- American Custom Carports

- American Steel Carports

- Arkansas Carports

- Best Choice Metal Structures

- California All Steel

- Carports Outlet

- Central Texas Metal Buildings

- Coast To Coast Carports

- Custom Steel Structures

- Dreams Carports and Buildings Inc

- East Coast Carports

- Enterprise Steel Structures

- Infinity Carports

- Interstate Steel Structures

- Long Horn Buildings

- Midwest Steel Carports

- NC Structures

- New Team Carports

- Northside Metal Carports

- Quality Carports

- Rhino Carports

- Safeguard Metal Buildings

- Southern Steel Buildings Inc.

- Steel Buildings and Structures

- Tennessee Steel Buildings

- Tubular Building Systems

- Ultimate Metal Buildings

- United Structures

- USA Carports