16

What Makes Corrugated Metal Paneling Better

Tough Building Needs Call for Tough Building Materials

Looking for a sturdy, reliable outdoor building solution? Don’t settle for any old stick build or pole barn. Choose metal buildings instead! What makes a steel-framed structure better? Pretty much everything you can think of. Galvanized steel tubing is really a perfect framing material. It’s strong, durable, relatively lightweight, and not susceptible to moisture, fire, or pests. And steel doesn’t rot, shrink, or warp; the same simply can’t be said for wood.

But while light-gauge steel tubing gets most of the fanfare when discussing metal buildings for sale, that’s not the only component worth considering when it comes to metal building kits. There’s also lots to like about the corrugated metal paneling used for roofing and exterior siding. And Carport Central is here to help educate and enlighten you!

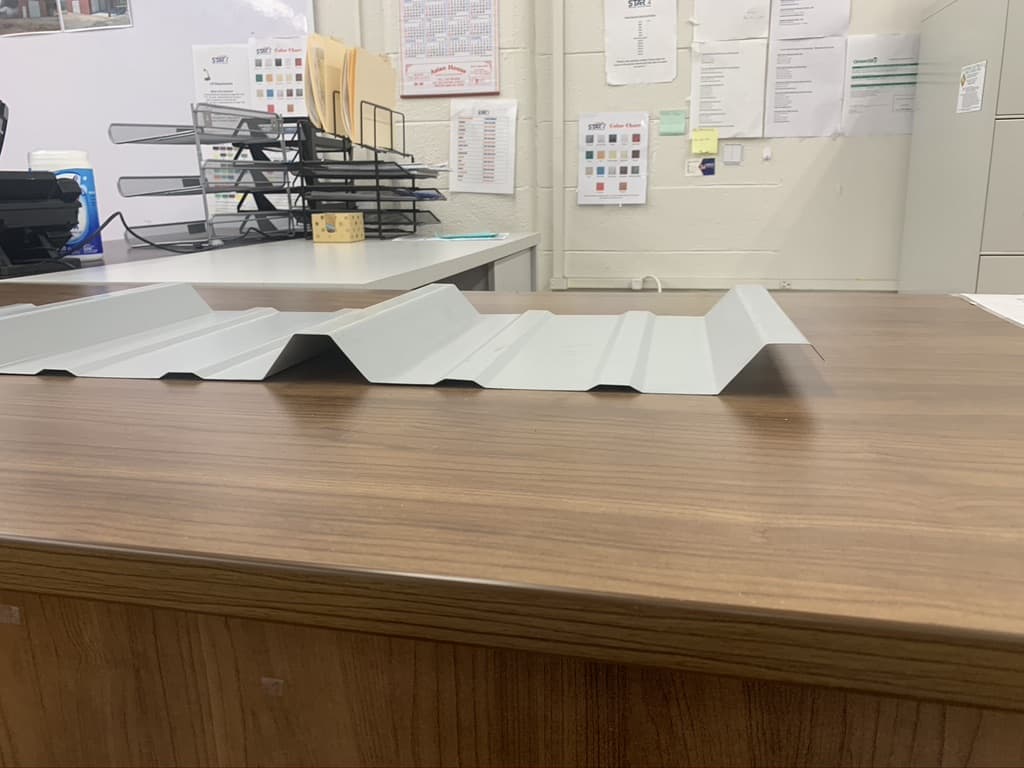

What Is Corrugated Metal?

You’re no doubt somewhat familiar with corrugated metal. You’ve certainly seen it in action, at least, as it’s been in common use as roofing and paneling for all sorts of outbuildings and other building types for many decades. But what is corrugated metal, exactly?

The word corrugated literally means “shaped into alternating ridges and grooves.” If you’ve ever ordered anything from Amazon (who hasn’t?!), you certainly know that corrugated cardboard makes for some pretty sturdy boxes. The same principle also applies to corrugated metal. Thanks to its ridged design, corrugated metal delivers some impressive structural strength while still being amazingly lightweight.

How Is Corrugated Metal Produced?

The metal components used in each of our buildings at Carport Central all start with cold-formed steel.

What is cold-formed steel? It begins with carbon steel, which is formed by combining molten iron ore or steel scrap with small amounts of carbon to increase hardness and strength. The molten steel is poured into thinner strips to cool, and then the steel rolls go through the galvanization process. A protective coating of zinc is added for helping to prevent corrosion. This zinc coating also enhances the luster and sheen of the steel’s appearance. Finished coils of galvanized steel can then be cold-formed into all sorts of building components of various thicknesses or “gauges,” including steel tubing for framing and roof trusses, as well as corrugated paneling to be used for roof paneling and side paneling. With these components, some impressively large metal buildings can be constructed to suit a wide variety of building applications.

Gauge Talk: Corrugated Metal Thickness

You’ve likely heard the term gauge before, as it relates to many metal products. Ever shot a firearm? The bore of the gun is fabricated to a specific gauge or diameter. A 12-gauge shotgun, for example, has a larger bore (and thus uses larger shot cartridges) than that of a 20-gauge shotgun.

But where metal structures are concerned, gauge refers to the thickness of specific building components. Steel frame tubing is most often fabricated from either 12-gauge steel (corresponding to a thickness of up to 0.1046 inches) or 14-gauge steel (equating to a thickness of up to 0.0747 inches). Likewise, corrugated steel paneling for roofs and side walls is most commonly fabricated from either 26-gauge steel (with a thickness of up to .0179 inches) or 29-gauge steel (with a thickness of up to .0149 inches).

Generally speaking, the lower the gauge number, the thicker, heavier, and stronger the steel is. Metal sheeting or paneling doesn’t require nearly the same thickness as frame tubing, but it’s still incredibly strong and resilient in its own right. The two most common corrugated metal gauges for roofing and side paneling are as follows:

- 29-gauge steel is a common choice for roofing and siding panels in general-use outdoor sheds, carports, garages, and storage buildings. 29-gauge paneling comes in a wide range of color options, as well. You can almost certainly find a color or color combination you like, whether you’re looking to make your metal building stand out or whether you’d prefer to help it blend in better with its surroundings. And with steel paneling, the colors are actually baked into the metal, so repainting isn’t usually necessary. That’s something else you can’t say about wood-based paneling!

- 26-gauge steel paneling is a step up from 29-gauge paneling. It costs a bit more, but its added thickness also makes it more resilient to hail or other dent threats. 26-gauge steel paneling generally carries a higher wind and snow load rating than 29-gauge paneling, too. If you’re planning to finish your metal building for residential living space or intend to use it for any commercial or industrial applications, going with the thicker 26-gauge paneling would be a wise choice.

So, What Makes Corrugated Metal Paneling Better?

There are several specific benefits and advantages of choosing corrugated metal paneling over other building materials for your roofing and exterior siding needs:

1. Strength and durability

It doesn’t get any stronger than steel, and that includes the steel used to make corrugated metal paneling.

2. Ideal roofing material

Metal sheds precipitation and debris better than other materials, particularly when mounted in a vertical orientation.

3. Built-in rust resistance

The galvanization and paint coating process makes this steel sheeting incredibly moisture- and rust-resistant.

4. Low-maintenance material

Cleaning can usually be handled with nothing more than a pressure washer or sprayer, and repainting isn’t generally required.

5. Faster, easier building assembly

Corrugated metal panels are relatively simple to install, and can be attached with metal fasteners much faster than some other building materials.

6. Aesthetically pleasing

Corrugated metal paneling looks good, and also delivers that signature pitter-patter sound whenever it’s raining. At Carport Central, we offer a full palette of color options to meet your tastes and preferences.

7. Made to last

Did you know? Metal roofing and paneling are rated to last anywhere from 40 to 80 years!

8. Eco-friendly

Metal isn’t petroleum-based, and has less of a carbon impact than many other building materials. Metal building components also include a minimum percentage of recycled materials, and the metal itself is essentially 100% recyclable. So yes, corrugated metal is one of the most eco-friendly options there is!

Carport Central Delivers Perfect Metal Building Solutions

Got questions about corrugated metal framing and paneling? Ready to start planning your own new perfect metal building? Connect with one of the friendly and knowledgeable building specialists at Carport Central! And for an even faster response, simply give us a call today at (980) 321-9898!

Get Started

It's fast and easy. Get your instant quote today!

BLOG TOPICS

- Condensation in Metal Buildings (2)

- News & Awards (12)

- Livestock sheds (4)

- Installations (15)

- Metal Buildings Applications (7)

- Customized Buildings (41)

- Carport Sizes (2)

- Facts (1)

- Certified Carports (2)

- COVID-19 (1)

- Prefab Metal Buildings (66)

- Metal Building Homes (6)

- Metal Building of the Week (11)

- Install of the week (1)

- Metal Building Extensions (1)

- Install of the month (2)

- Garages (52)

- Farm Show (1)

- Building Components (1)

- Carports (29)

- Storage Sheds (15)

- Metal Buildings (6)

- Barns (18)

- Metal Homes (8)

- Metal Sheds (1)

- RV Covers (6)

- 12 Gauge Framing (7)

- Workshops (7)

- Eagles & Buildings (1)

- Reviews (2)

- Snowfall in the Southeast (2)

- Carports and Buildings Prices (1)

- Reality Of Discounted Buildings (2)

- Snow Removal (1)

- Offers (3)

Metal Buildings

- Alabama

- Arizona

- Arkansas

- California

- Colorado

- Connecticut

- Delaware

- Florida

- Georgia

- Idaho

- Illinois

- Indiana

- Iowa

- Kansas

- Louisiana

- Maine

- Maryland

- Massachusetts

- Michigan

- Minnesota

- Mississippi

- Missouri

- Montana

- Nebraska

- Nevada

- New Hampshire

- New Jersey

- New Mexico

- New York

- North Carolina

- North Dakota

- Ohio

- Oklahoma

- Oregon

- Pennsylvania

- Rhode Island

- South Carolina

- South Dakota

- Tennessee

- Texas

- Utah

- Vermont

- Virginia

- Washington

- West Virginia

- Wisconsin

- Wyoming

Metal Garages

- Alabama

- Arizona

- Arkansas

- California

- Colorado

- Connecticut

- Delaware

- Florida

- Georgia

- Idaho

- Illinois

- Indiana

- Iowa

- Kansas

- Louisiana

- Maine

- Maryland

- Massachusetts

- Michigan

- Minnesota

- Mississippi

- Missouri

- Montana

- Nebraska

- Nevada

- New Hampshire

- New Jersey

- New Mexico

- New York

- North Carolina

- North Dakota

- Ohio

- Oklahoma

- Oregon

- Pennsylvania

- Rhode Island

- South Carolina

- South Dakota

- Tennessee

- Texas

- Utah

- Vermont

- Virginia

- Washington

- West Virginia

- Wisconsin

- Wyoming

Metal Carports

- Alabama

- Arizona

- Arkansas

- California

- Colorado

- Connecticut

- Delaware

- Florida

- Georgia

- Idaho

- Illinois

- Indiana

- Iowa

- Kansas

- Louisiana

- Maine

- Maryland

- Massachusetts

- Michigan

- Minnesota

- Mississippi

- Missouri

- Montana

- Nebraska

- Nevada

- New Hampshire

- New Jersey

- New Mexico

- New York

- North Carolina

- North Dakota

- Ohio

- Oklahoma

- Oregon

- Pennsylvania

- Rhode Island

- South Carolina

- South Dakota

- Tennessee

- Texas

- Utah

- Vermont

- Virginia

- Washington

- West Virginia

- Wisconsin

- Wyoming

- 100x100 Metal Building

- 12x12 Metal Shed

- 12x20 Carport

- 12x24 Carport

- 12x30 Carport

- 16x20 Carport

- 18x20 Carport

- 20x20 Carport

- 20x20 Metal Building

- 20x30 Carport

- 20x30 Metal Building

- 20x40 Carport

- 20x40 Metal Building

- 24x24 Carport

- 24x24 Garage

- 24x30 Carport

- 24x30 Metal Building

- 24x30 Metal Garage

- 24x36 Metal Building

- 26x30 Metal Building

- 30x30 Carport

- 30x30 Garage

- 30x30 Metal Building

- 30x40 Carport

- 30x40 Garage

- 30x40 Metal Building

- 30x40 Storage Building

- 30x50 Metal Building

- 30x60 Metal Building

- 40x100 Metal Building

- 40x40 Metal Building

- 40x60 Metal Building

- 40x80 Metal Building

- 50x100 Metal Building

- 50x50 Metal Building

- 50x80 Metal Building

- 60x100 Metal Building

- 60x120 Steel Building

- 60x60 Metal Building

- 60x80 Metal Building

- 80x100 Metal Building

- All Steel Carports

- American Building Network

- American Custom Carports

- American Steel Carports

- Arkansas Carports

- Best Choice Metal Structures

- California All Steel

- Carports Outlet

- Central Texas Metal Buildings

- Coast To Coast Carports

- Custom Steel Structures

- Dreams Carports and Buildings Inc

- East Coast Carports

- Enterprise Steel Structures

- Infinity Carports

- Interstate Steel Structures

- Long Horn Buildings

- Midwest Steel Carports

- NC Structures

- New Team Carports

- Northside Metal Carports

- Quality Carports

- Rhino Carports

- Safeguard Metal Buildings

- Southern Steel Buildings Inc.

- Steel Buildings and Structures

- Tennessee Steel Buildings

- Tubular Building Systems

- Ultimate Metal Buildings

- United Structures

- USA Carports